Design and production of prefabricated wood facades

Does your building envelope serve your energetic performance and your carbon footprint?

Dress up your building with a biosourced, prefabricated, and bespoke facade

For new-builds or refurbishment projects, we offer our public and private sector clients as well as general contractors, a wide range construction contracts and supply contracts of :

- complete facade panels on PANOBLOC (R): a CLTi (CLT+insulation) wood-frame facade with technical approval, clad and equipped, made in France

- complete wood-frame wall panels or traditional wood-frame facades

Thanks to our factory-finished facades, you benefit from a number of advantages :

- organizational : reduced nuisance, optimized construction times, global cost considerations

- ecological : French production, low-carbon solutions and bio-sourced materials

- and energy : reduced consumption, thermal performance, elimination of thermal bridges, etc.

As the leading designer and manufacturer of prefabricated wood facades, with an industrial production capacity of 80,000 m² of facades per year, we are working to decarbonize construction and real estate.

Support and assistance throughout the entirety of your project

Support ahead of the project

Analysis of projects: execution details book, monitored under ATEx

Supply of bare or partially equipped or finished facades

Support services for panel installation provided

Complete management of facade batches and panel installation

We supply bare or finished panels

With an industrial production of 80,000 m² of facade per year, we supply bare or finished pannels (facings, joinery, cladding, etc.) directly from our workshops.

Our wood-frame panels consist of a structure that we determine at the design and analysis stage (wood-frame walls panels, traditional wood-frame facades and PANOBLOC).

On either side of this structure, we add bracing panels, waterproofing films, facings, etc., according to your technical requirements.

Inside this structure, we install all types of insulation (mineral, synthetic or natural) in order to suit your needs.

In our workshop, we integrate all types of joinery to enable the enclosed structure to be closed as soon as the panels are installed on site.

PANOBLOC® revolutionizes timber frame facades

We have invented the new generation of timber frame facades.

Designed from bio-sourced and low-carbon materials, Panobloc® is a 100% French, eco-designed and sustainable product.

It integrates effective wood fiber or rock wool insulation into its timber structure.

Thanks to its multilayered assembly, Panobloc® offers thicknesses and performances tailored to each project. It can be installed as a curtain wall, external wall insulation, or integrated into the concrete cycle.

Although industrially manufactured, Panobloc® offers great flexibility to adapt to each project by adjusting:

- The number of layers (3 to 5) to optimize thermal, fire and acoustic performance;

- The dimensions of the panels and openings to suit the project's architecture.

A wide range of finishing options

The integration of all types of external claddings adaptable to wood panels is possible: ventilated sidings, solid or composite wood, cladding or metal cassettes, mineral or composite panels, non-ventilated sidings...

It is also possible to integrate all types of windows and exterior joinery, including doors, window surrounds, blinds, and sunshades...

A unique rendering for each project

Our completed projects and references

BICHAT-TEMPLE - Façades bois & zinc pour les 6 bâtiments de la résidence

Construction d’un ensemble de 6 bâtiments de grande envergure composé d’une crèche tout bois de 66 berceaux recouverte de verdure et d’arbres, de 91 logements sociaux (mixte bois/béton) et 14 logements bois en attique couverts de toiture Shed, 2 locaux commerciaux de 600 m2 et 98 places de parking.

Le bâtiment est simple et compact pour la qualité environnementale, confortable et pérenne pour les locataires.

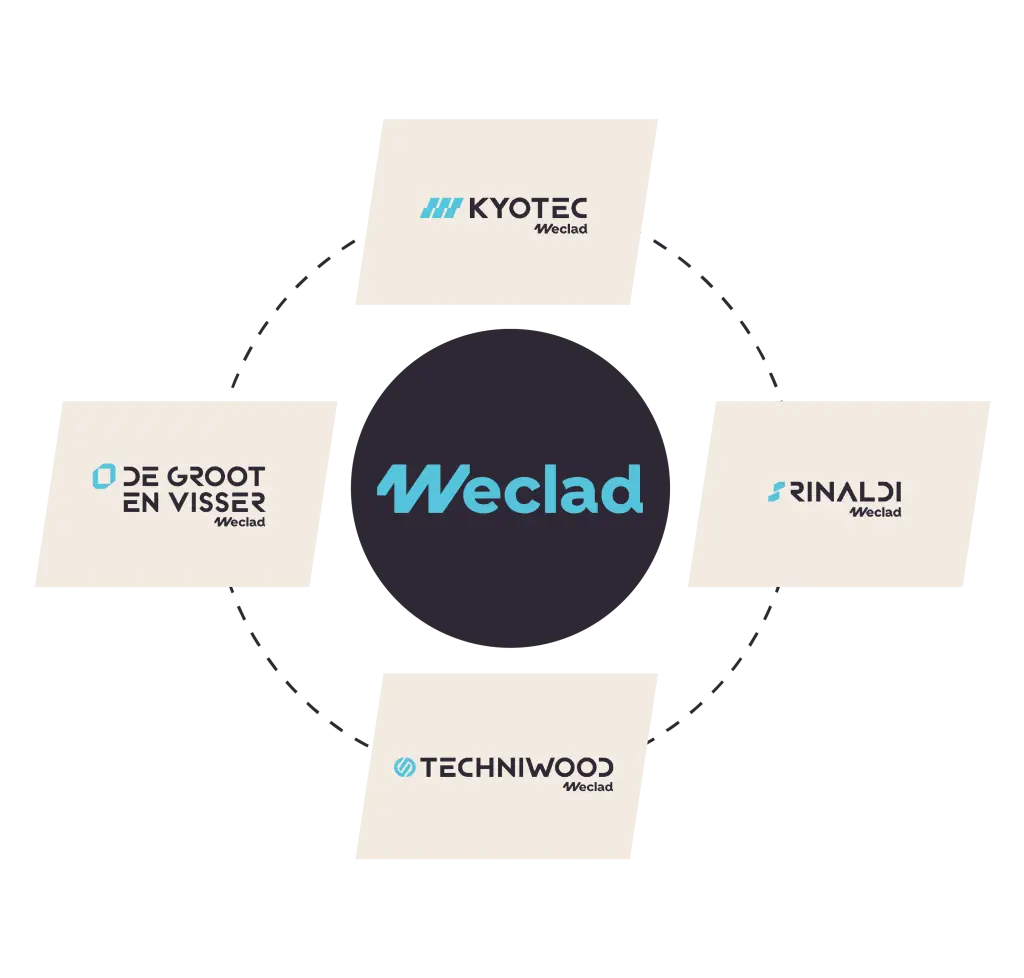

Weclad : the alliance of four leading facade manufacturers

Techniwood has joined forces with 3 other European facade manufacturers to create the Weclad alliance. This has enable us to increase our industrial potential tenfold and offer you large-scale bio-sourced facade solutions.

Working in collaboration with Kyotec, Rinaldi and De Groot & Visser, we benefit from a multisite production capacity that allows us to meet the most demanding needs while reducing the carbon footprint of each project.

This pooling of industrial resources strenghtens our expertise and ensures facades that combine innovation, durability, and performance, even on the most complex projects.